Manufacturer for high quality wear parts and components

Through many years of experience and close cooperation with our customers, we know what matters in practice.

The high degree of vertical integration based on an extensive and highly technical machine park enables us to realise your desired product. Our own toolmaking department ensures that your ideas are implemented quickly. This is why we can also flexibly implement your special requests in the best OEM quality.

A modern ERP system supports order acceptance, production planning, material disposition, production optimisation and quality inspection. The highly complex processes thus remain transparent. Our clear product batching ensures best quality up to the application at the end customer.

2D-Laser

- Modern energy-efficient fibre laser with fully automatic discharge

- Large fully automatic material storage

- Best cut in almost all materials

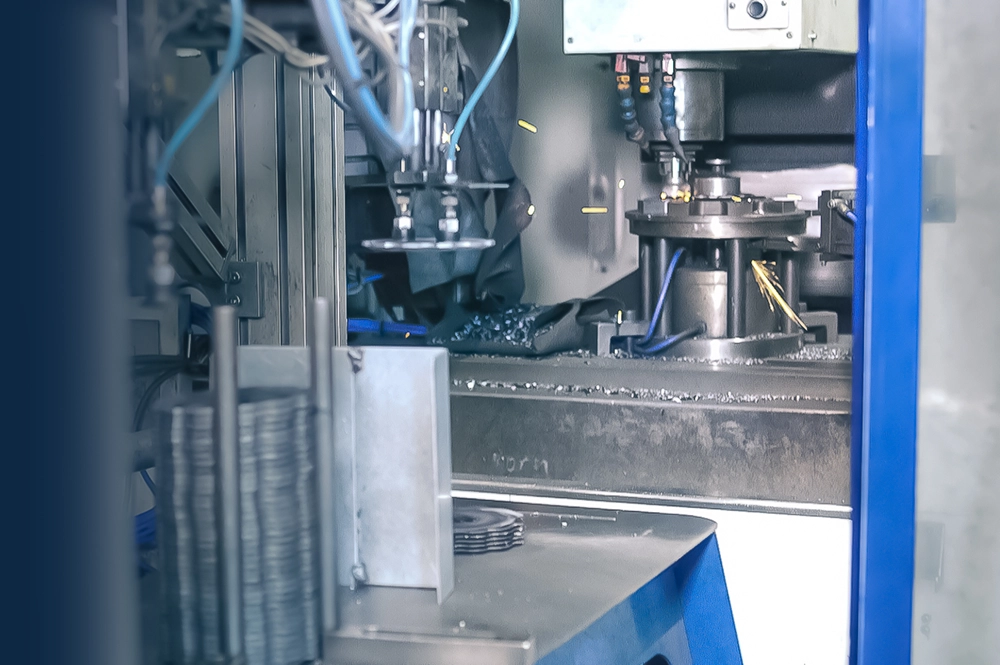

CNC machining

- Modern CNC machining centres with large working area

- Stable cast iron machine beds for high precision

- Partially automated loading and unloading

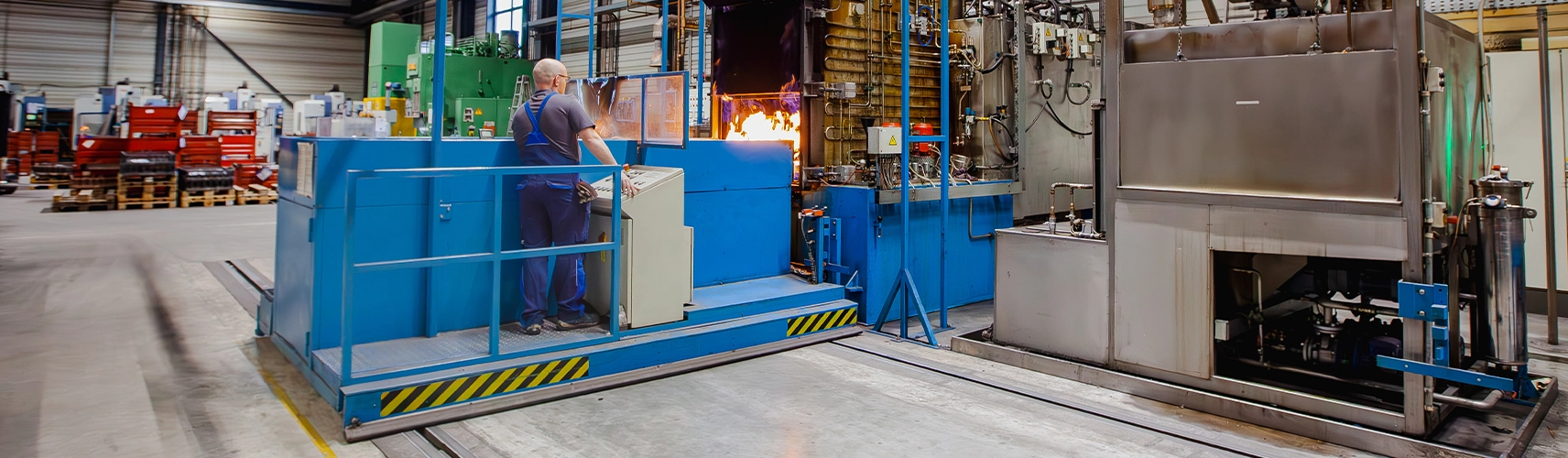

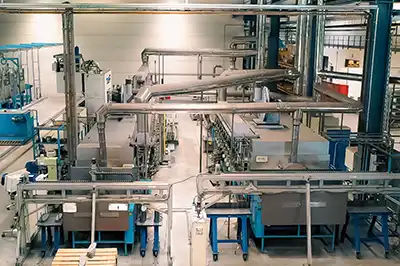

Hardening line 2

- Fully controlled roller hearth Protective gas furnace

- Recuperator burner

- Environmentally friendly press hardening process without quenchants

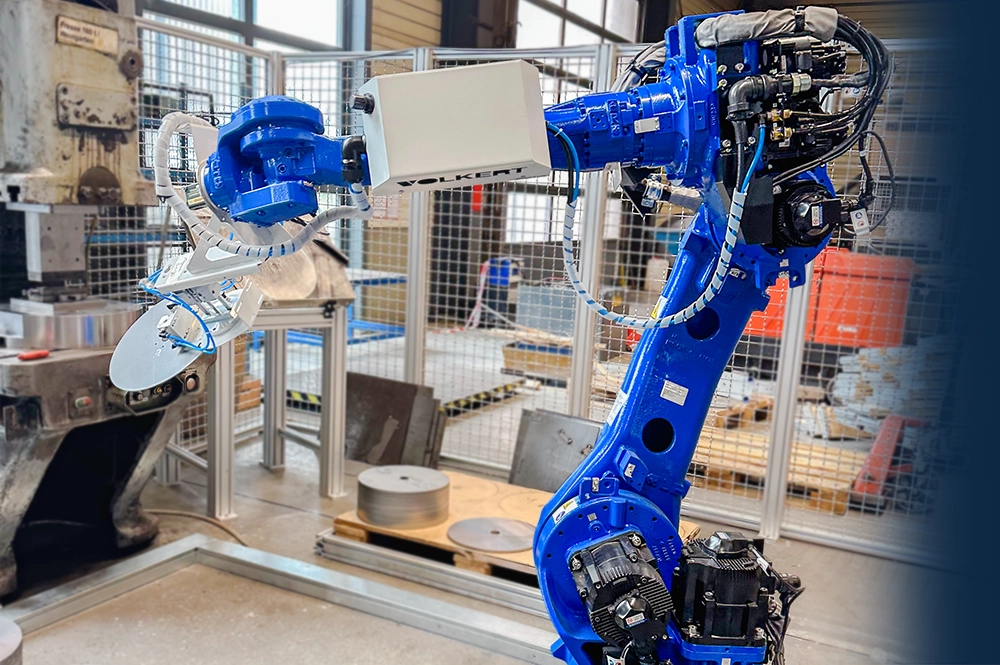

- Robot handling

Hardening line 3 MZK

- Protective gas chamber furnace

- Hardening under protective gas in oil bath

- Carburising, completely programme-controlled process

PTA coating rice cells

- Cells with program-controlled parameters (current, shielding gas, filler metal, welding speed)

- Shuttle table system with robot-guided torch

PTA coating Kuka

- Program-controlled parameters

- Components are moved by the robot, making complex 3D contours possible

- Torch always in tub position

Lasercladding

- Latest laser technology for laser build-up welding

- Automatically controlled application of an abrasion-resistant protective layer to surfaces of tools that are subject to particularly high levels of wear

- Ideal for difficult contours on workpieces

- Significant energy and material savings compared to conventional processes such as PTA coatings

- Fully controlled roller hearth Protective gas furnace

- Fully controlled

- Modern efficient recuperator burners with automatic loading

- Hardening device for thin, flat parts

- Optimum flatness, belt tempering furnace

- Induction brazing systems with automatic sequence

- Complex workpieces possible

- Various brazing systems possible

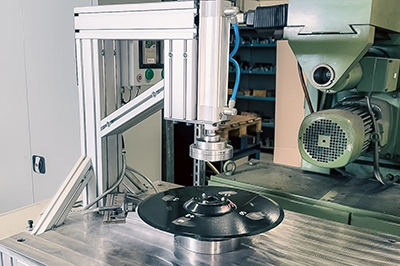

- Automatic, program-controlled sequence with 6-axis movement

- Automatic stone compensation

- Optimum cooling system

- Specially manufactured grinding stone recipes

- Environmentally friendly powder coating with automatic coating without solvents as well as waste water free

- Automated process

- Medium frequency

- Simultaneous hardening from two sides with low distortion

- Polymer quenching

- Certification according to DIN EN ISO 9001

- Complete traceability

- Regular training and further education measures

- CAD/CAM system

- In-house design with many years of experience in cutting and forming tool construction

- Special press hardening tools

- Manufacturing without drawings

OEM TEC GmbH

We, OEM TEC GmbH, are a leading manufacturer of knives in the industrial sectors of garden and agricultural technology. Our team of specialists and engineers develops products from the idea to series production. Thanks to special hardening techniques, our blades impress with above-average quality and long service lives.

Certified quality

Quality has always been the focus of our actions – we are DIN ISO 9001:2015 certified accordingly.Read more